Ready to Get Started?

Try Autodesk Platform Services for free by setting up an account and free trial. Explore the resources to learn about the solutions you can build using design and engineering data.

JFE Engineering provides engineering, procurement, construction, and operations and maintenance services for plants and facilities. Based in Japan, JFE Engineering was launched in 2003, owned by the parent JFE Holdings which was jointly established by NKK and Kawasaki Steel. JFE Engineering Group employs roughly 10,000 people, including JFE Engineering employing about 4,000. The company is a key player in energy, environment, urban infrastructure, and industrial machinery, operating through recycling, power generation and electricity, waste management, water and sewage, pipelines, energy plants, bridges and steel structures, and industrial machinery.

To store the entirety of JFE Engineering’s data, the firm relies on the cloud storage system Box. During project development and fulfilment, stakeholders frequently need to easily access 3D model data. Box supports a 3D model viewer, but it is unable to display 3D models in Navisworks, Revit, and IFC formats—the software that JFE Engineering uses predominantly. To negotiate this problem, the firm’s engineers would view 3D models with a dedicated 3D viewer that they’d installed on a high-performance PC, or they’d upload the 3D model to an additional cloud service with 3D viewing capabilities. The complexity and hassle of these procedures were discouraging engineers from using 3D models in their projects, and 2D paper-based drawings were still the norm, which was time- and resource-consuming and complicated project feedback and collaboration.

JFE Engineering knew that 2D drawings were a dead-end street, and to encourage stakeholders to use 3D models, the firm decided to develop an environment that easily supported 3D model viewing and checking. Requirements were simple: Models had to be displayable directly from Box on any device through a browser-based web application. The environment had to be capable of displaying a wide variety of file formats, and easy to operate, customizable, and scalable. Finally, the firm was aiming for low cost with no need for dedicated machines or additional licenses beyond Box.

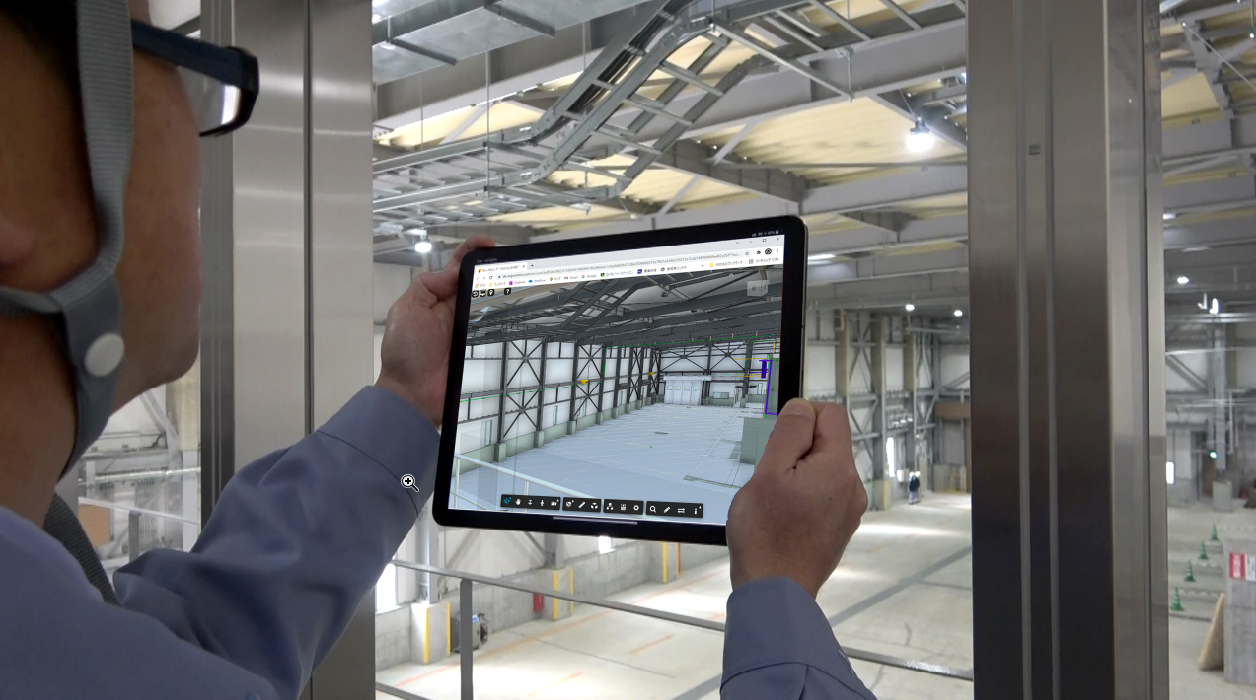

Forge fit the bill. Incorporating the powerful platform into Box, the JFE Engineering team uploads files into the Model Derivative API. The API then translates them into 3D models that stakeholders can view and manipulate in the Viewer API on web-based browsers across any device, whether in the office or the field.

As the Model Derivative API can translate more than 70 file formats, the process is hassle-free, instantaneous, and doesn’t require extra licenses or hardware. Plus, stakeholders can collaborate in real time while simultaneously viewing the model and using the Forge markup function. The result is nothing less than a transformation in project workflows, democratizing data, speeding completion, and reducing errors and cost.

Forge highlights include the following:

“Forge is an indispensable platform for facilitating engineers’ work with 3D models.” — Hideo Kasuya; General Manager, ICT Center Technology Headquarters, JFE Engineering Corporation