Aftermarket Needs a Digital Shift

Manufacturers face a critical challenge: how to scale aftermarket operations without adding cost and complexity. Aftermarket, which includes service, spare parts, and maintenance, has traditionally been slowed by manual workflows, scattered data, and reactive support.

For many years, aftermarket processes have lagged behind innovation in design and production. Spreadsheets, PDF manuals, and phone-based support are still common. This fragmented model frustrates customers, increases downtime, and leaves significant revenue untapped.

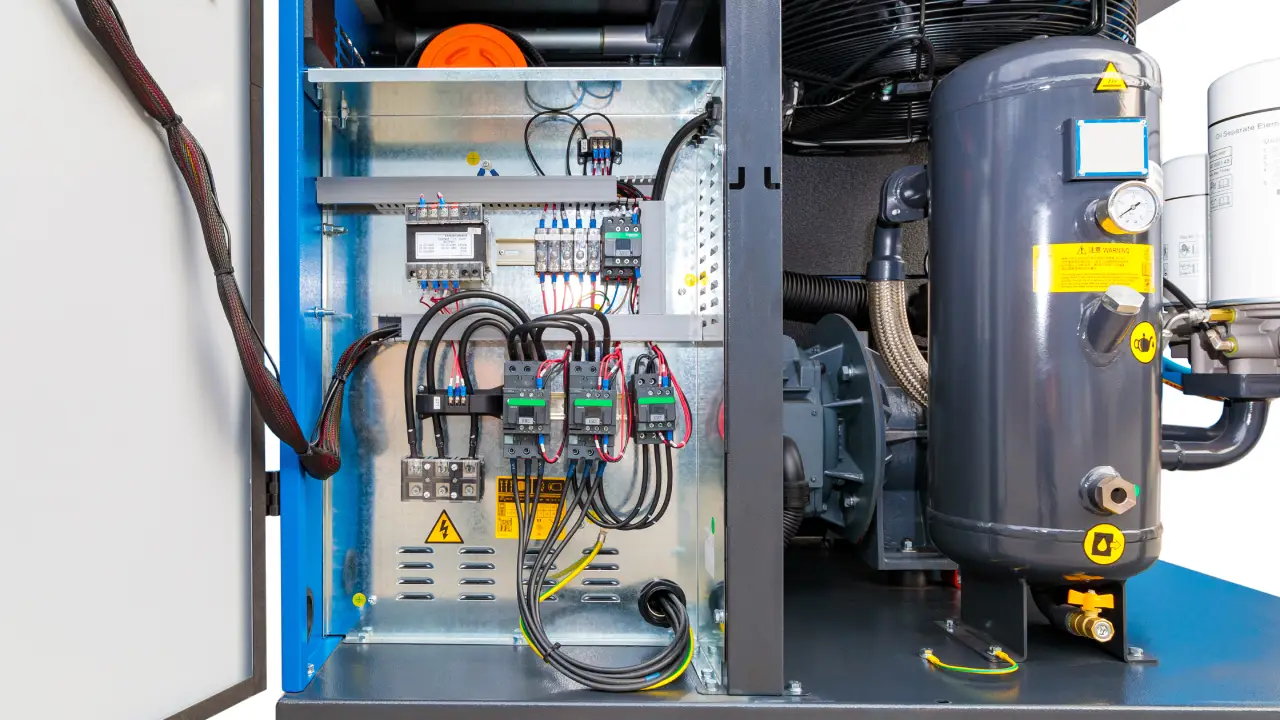

Industrility working in partnership with Autodesk, addresses this gap with a cloud-based aftermarket solution. At its core is a Digital Twin approach. Every machine sold is represented in a portal as a living, interactive model linked with real-world data. Customers and technicians can log in, identify parts using 3D visualization, check availability, and place orders instantly.

This transforms aftermarket into a growth engine rather than only a support function. Manufacturers gain a structured system to capture revenue, improve service efficiency, and deliver proactive customer care.

Deep Integration with Autodesk Partner and Developer Network:

Industrility works closely with Autodesk’s Partner and Developer ecosystem, integrating with solutions such as Autodesk Platform Services, Autodesk Vault PLM, and Autodesk Construction Cloud to help manufacturers unlock the full value of their engineering data.

The power of Integrating with APS APIs

The solution leverages key Autodesk Platform Services (APS) APIs to transform engineering data into operational aftermarket tools. Using the Model Derivative / Model Translate API, CAD models are converted into lightweight 3D/2D assets for BOM Explosion. With the Viewer API, these models become fully navigable digital twins that link directly to parts, manuals, and service workflows. Together, these APIs enable OEMs to repurpose engineering data at scale and deliver seamless 3D parts catalogues and self-service e-commerce experiences.

This seamless connectivity allows manufacturers to deliver 3D parts identification, 2D navigation for mechanical and electrical diagrams, and self-service e-commerce experiences directly from accurate engineering sources, reducing errors, eliminating manual data handling, and creating a unified aftermarket environment that scales globally.

Technology Impact for OEMs

This technology integration enables OEMs to unlock new aftermarket revenue opportunities throughout the lifetime of every asset. Customers can identify parts directly from the 3D digital twin, place orders through connected e-commerce flows, and access manuals, BOMs, and maintenance records in a unified portal.

By eliminating guesswork and manual data handling, manufacturers speed up quoting, reduce returns, and ensure the right part is ordered the first time - delivering a smoother, more accurate customer experience at scale.

Real Impact – Birth of The Operational Digital Twin

Through its partnership with Autodesk, Industrility is leveraging the design time artifacts and converting them for operational use. The Operational Digital Twin is story of machine after its sold. Industrility enables manufacturers to digitize asset lifecycle management, streamline parts and service management, and create modern 3D parts catalogues and e-commerce solutions, specifically for machine manufacturers so that they can serve tier customers better.

Two leading manufacturers highlight the impact:

- A hydrogen compression equipment provider digitized its installed base of more than 2,000 machines, launched a branded aftermarket portal, and achieved a 50% increase in service and parts revenue.

- A global infrastructure equipment manufacturer improved quoting efficiency by 82%, reduced parts returns by 50%, and standardized workflows across international operations.

These stories point to a broader truth: digital aftermarket transformation is no longer optional. It is the key to building loyalty, efficiency, and revenue in modern manufacturing.

Best of Both the worlds: Industrial Metaverse + Generative AI

The future of aftermarket lies in combining immersive 3D experiences with intelligent automation. The Industrial Metaverse brings machines to life through interactive digital twins, enabling remote diagnostics, training, and real-time collaboration. Layered with Generative AI, the system becomes proactive, guiding technicians with smart recommendations, predicting failures, and automating service decisions.

Together, these technologies help manufacturers fix issues faster, reduce downtime, and deliver a modern, self-service customer experience.

Benefits are real

The lessons from these manufacturers apply broadly across the industrial sector and brings new perspectives

- Scale Without Expanding Headcount

Automated quoting, self-service portals, and digital workflows enable service teams to handle more customers efficiently. - Strengthen Customer Loyalty

An intuitive digital experience signals commitment to long-term support, improving customer retention and lifetime value. - Move to Proactive Service

Centralized asset data and AI readiness allow predictive maintenance and proactive care, reducing downtime. - Unlock New Revenue Streams

Structured digital systems make it easier to introduce extended warranties, subscriptions, and premium service models.

Aftermarket, once overlooked, is becoming one of the most important levers for sustainable profitability.

Conclusion: The Future of Aftermarket

The partnership between Autodesk and Industrility shows what is possible when advanced visualization meets industry-specific expertise. Together, they are turning aftermarket into a source of efficiency, loyalty, and growth.

By combining Autodesk technology with Industrility’s SaaS innovation, manufacturers can offer interactive 3D parts catalogues, seamless 3D parts e-commerce, and comprehensive asset lifecycle management in a single solution.

The message is clear: digital aftermarket is not just about support. It is about creating a competitive edge for the future.