Ready to Get Started?

Try Autodesk Platform Services for free by setting up an account and free trial. Explore the resources to learn about the solutions you can build using design and engineering data.

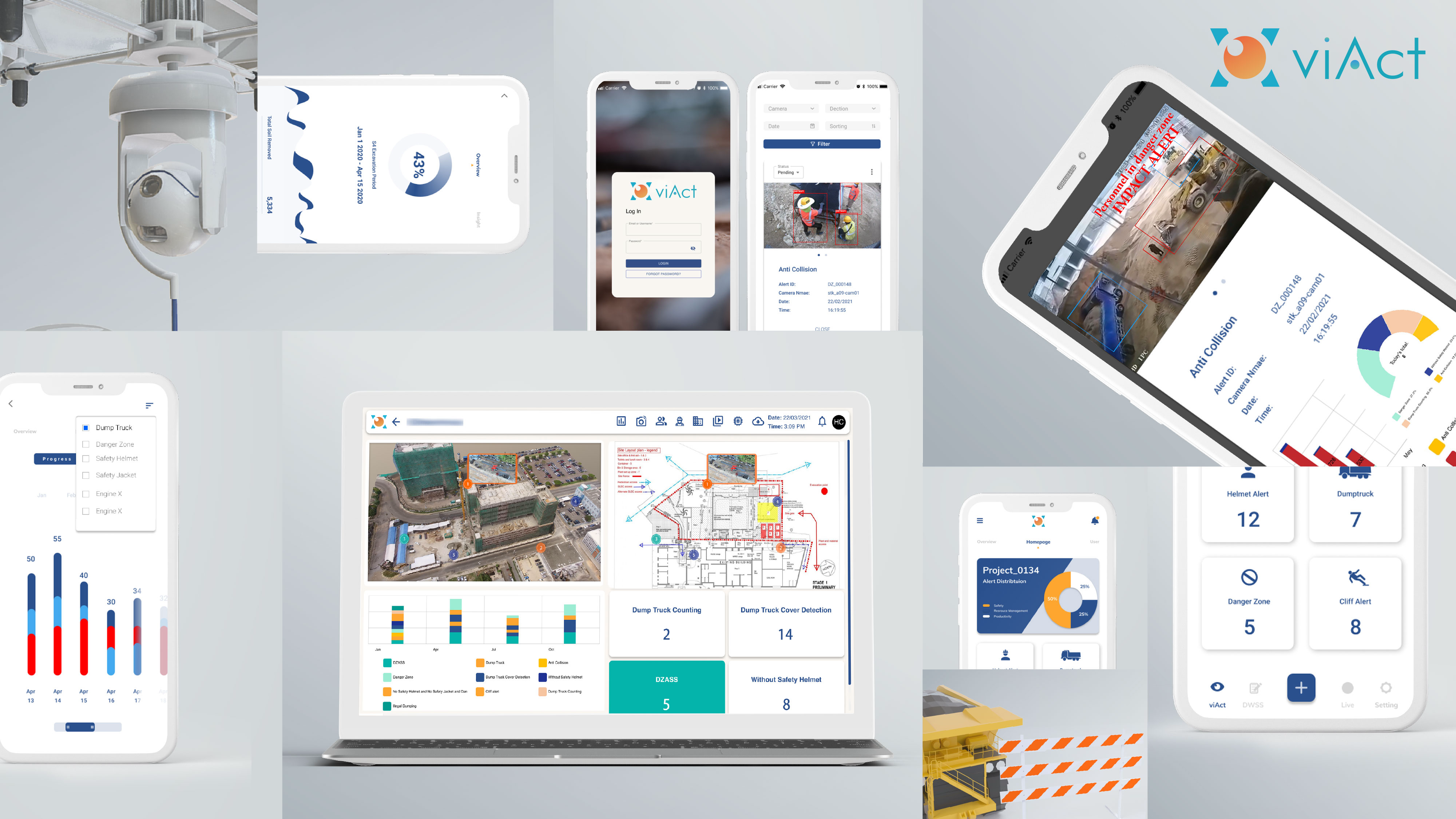

Since 2016, Hong Kong-based viAct has been providing the construction industry with cloud-based, real-time, round-the-clock, automated monitoring solutions designed to optimize safety, productivity, and compliance on construction sites. The company has developed more than 50 solutions based in AI and Internet of Things (IoT) for a variety of construction environments, monitoring issues that range from the macro (project productivity) to the equally important micro (worker cigarette smoking). Located in one of the fastest-growing construction markets, viAct currently serves customers in Asia and Europe, and is expanding into Indonesia, Vietnam, and Singapore.

Boots on the ground has traditionally been the way construction companies have kept an eye on construction sites. Site inspectors typically monitor worker safety and fatigue, team productivity, respect of health regulations, equipment integrity, and security of materials and equipment by walking around a site. But inspectors cannot be in all places at all times, which, coupled with possible fatigue and waning attention, can also lead to costly errors that endanger worker safety and curb productivity. Add to these limitations the complications of the COVID-19 lockdown, and construction companies have increasingly pivoted to remote monitoring of sites.

viAct has accumulated a massive data base that enables the company to develop AI-based solutions for a wide variety of construction sites, and demand for viAct’s services has grown over the last 18 months. But the company was running into problems representing projects’ multiple-floor 3D models in the viAct 2D viewing system, which frustrated stakeholders who wanted to more accurately monitor activity, height, and position in 3D.

Initially, viAct explored various 3D viewing options to integrate into its software systems, but these tools were limited to viewing capability. As the firm saw the long-term value of aligning its solutions with construction and model data sets—including post-construction operations and maintenance functionality—team members expanded the search to include software that extracted the BIM (Building Information Modeling) data increasingly built into construction project models. The Forge platform and its comprehensive APIs were a clear choice.

Using these APIs, viAct software empowers the customer to upload native 3D models directly into the viAct system. The Model Derivative API extracts and translates the model files, rendering them into a 3D model that the Viewer API makes viewable in any basic web-based browser. The Viewer and the Data Visualization API extensions are used to display cameras on the intelligent model. Users can then customize camera position, orientation, focal length, and scope of view.

The result is a cloud-based digital twin that provides complete 3D monitoring capabilities to track everything site related, from structure to machine to human. With its comprehensive, interactive, accurately placed system of cameras, stakeholders can use a web-based browser to move throughout the site from any location in the world on any device. AI detection initiates real-time alerts that enable customers to enforce safety regulations, track productivity, and ensure theft prevention.

Furthermore, by aligning with the project data set, viAct software can detect particularities of site progress (the 50% completion of a wall, for example) and revise the intelligent project model in real time so that stakeholders can easily remain up to date and make more accurate decisions faster. Click HERE for additional reference materials on their BIM 360 integration or to request a follow-up from viAct.

Forge highlights include the following:

“Forge is the ultimate solution for us to improve our clients’ site comprehension and monitoring.” — Gary Ng, CEO and Cofounder, ViAct